Robotics companies are racing to perfect humanoid hands, but replicating human-level dexterity remains one of the industry’s toughest challenges.

At London-based Shadow Robot, early prototypes built with wood and rubber bands have evolved into motor-driven hands with precision metal tendons.

Around 200 of its robotic hands are used globally, mainly as research tools to advance manipulation and fine motor control.

Developers say the hand is the most complex component of humanoid robots, critical for navigating environments built for humans.

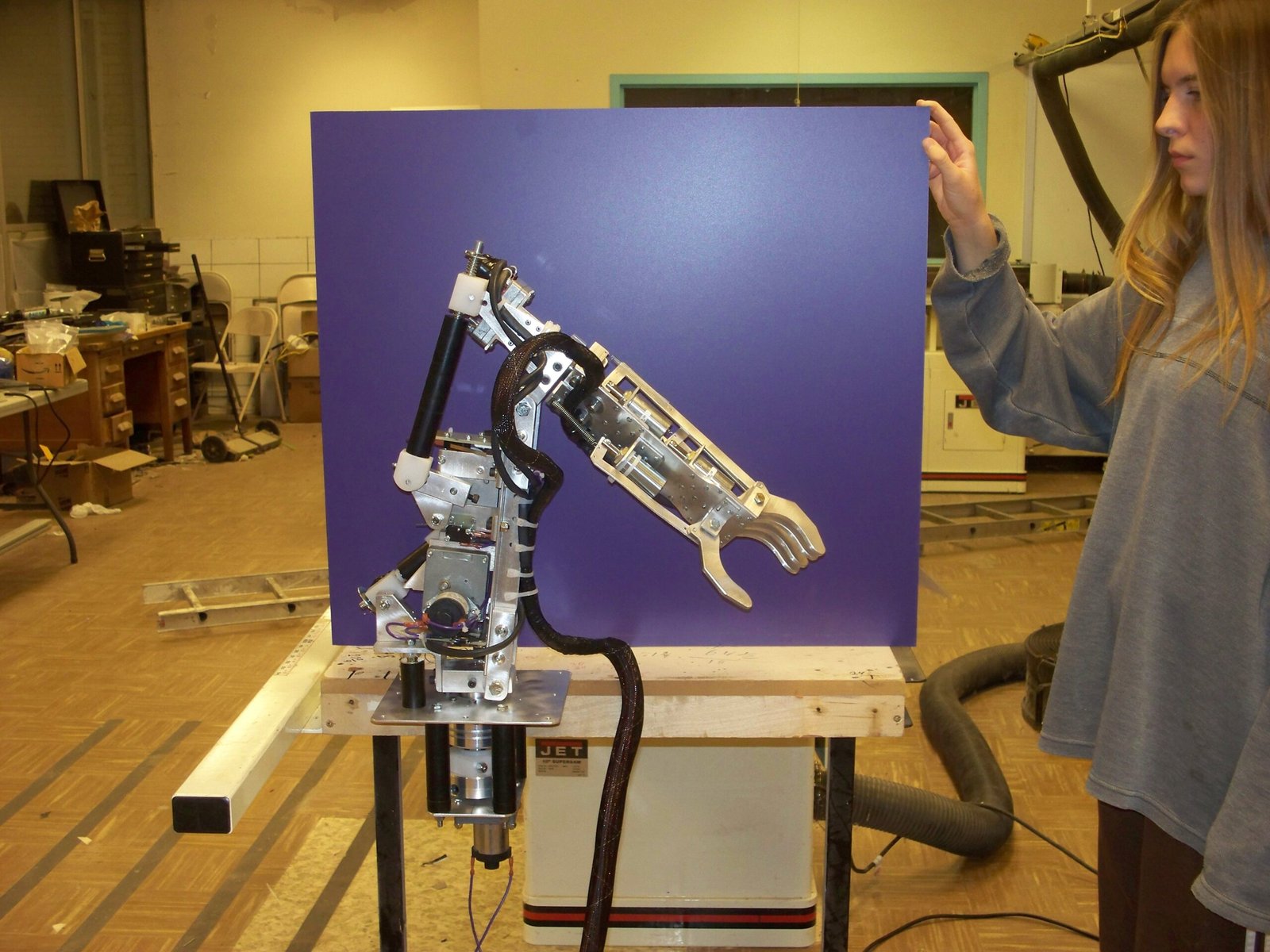

Bristol startup Kinisi has created a three-fingered prototype, but scaling production and reducing its £4,000 cost remain major hurdles.

Tesla CEO Elon Musk recently called advanced robotic hands one of the three hardest problems in humanoid robotics, alongside AI and mass production.

Experts caution that true human-like manipulation may still be a decade away, despite rapid progress and rising investment.

Chinese firms such as Shanghai-based Wuji Technology are developing sensor-equipped hands with enhanced durability, aiming to deliver affordable tactile intelligence at scale.